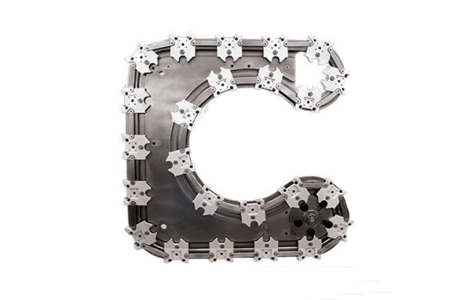

Tool changing devices for CNC machines enable rapid transfer of tools in and out of the machine and are available in standard format with either a circular carousel or oval track the most common configurations.

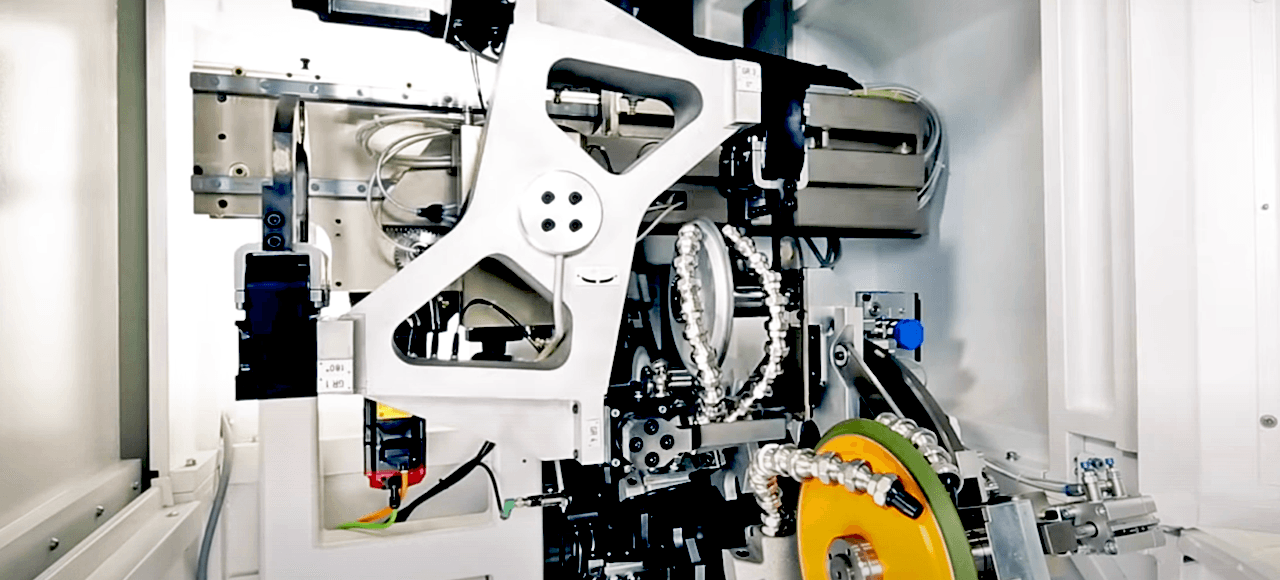

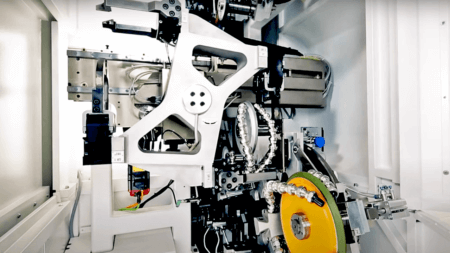

However, when Walter Maschinenbau wanted to develop a new CNC controlled Helitronic tool grinder they needed a product that could link 12 or 24 x 254mm diameter grinding discs and traverse them around a circuit without them clashing. In principle this did not sound too demanding until the space available to fit the tool changer into was revealed.

With no suitable solution evident, Walter turned to linear motion experts HepcoMotion to see if a standard PRT2 track system could fit into the limited available space. Initial investigations were promising but the aspect of preventing the discs clashing as they went around the curved sections of the track was proving challenging. The obvious option of just lengthening the track was not possible with the space available. There was also the requirement for the control system to be able to demand any wheel in the circuit and bring it to a predetermined position within a positional accuracy of 0.050mm.

Solution

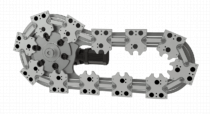

A 1-Trak system machined from a single plate of a prorietary tool steel so that there was no assembly of track parts would provide the basic base plate for the tool changer. The plate included the vee track machined in, plus the cam profile for the carriage drive pins to follow. A separate drive wheel with slots to allow the pin movement was driven by a motor / helical bevel gearbox arrangement attached from the rear of the base plate.

Scope of Supply

Complete 1-Trak system complete with mechanical drive system.

Result

A compact easy to install low maintenance tool changer system, the Hepco standard bleed lubrication system for the track was installed to ensure a measured amount of lubricant was distributed to the V guide ensuring long life. In a lubricated 1-Trak system the limiting factor is the life of the bearings calculated at many thousands of kilometers. In the unlikely even of the bearings needing changing it is a simple task to release the V bearings from the carriage and effect replacement.

Recommended for you

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form