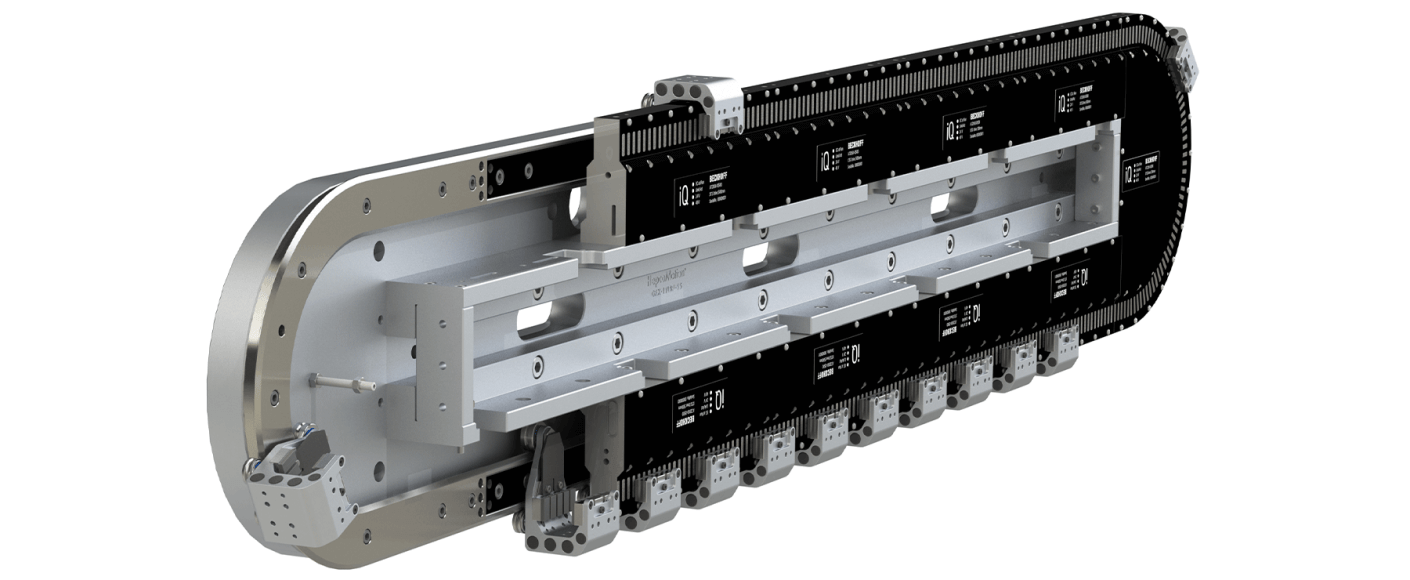

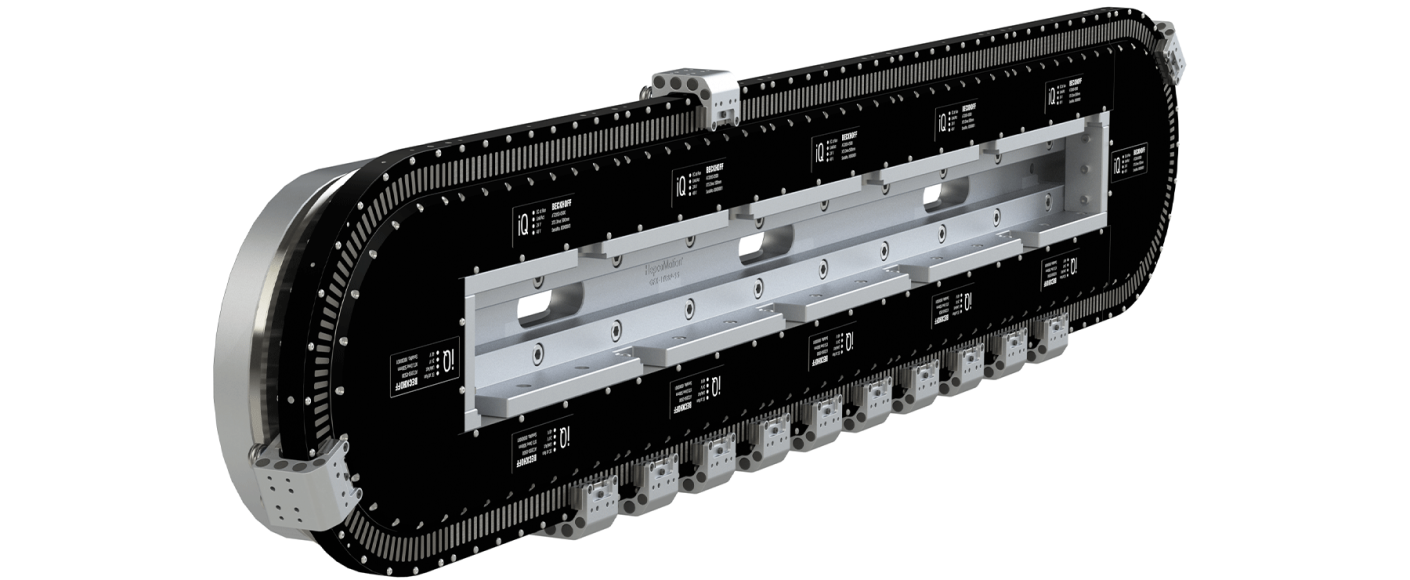

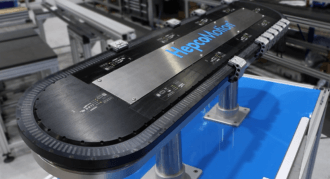

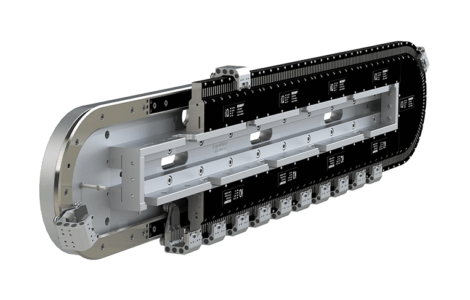

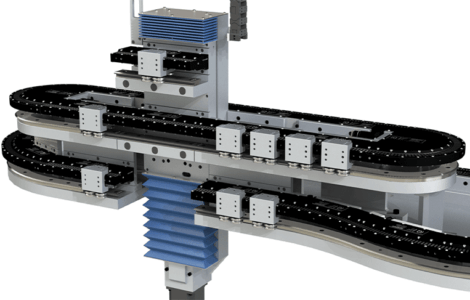

GFX Agile is a very low mass variant of the standard GFX Guidance System for Beckhoff XTS, providing higher accelerations to achieve a higher throughput.

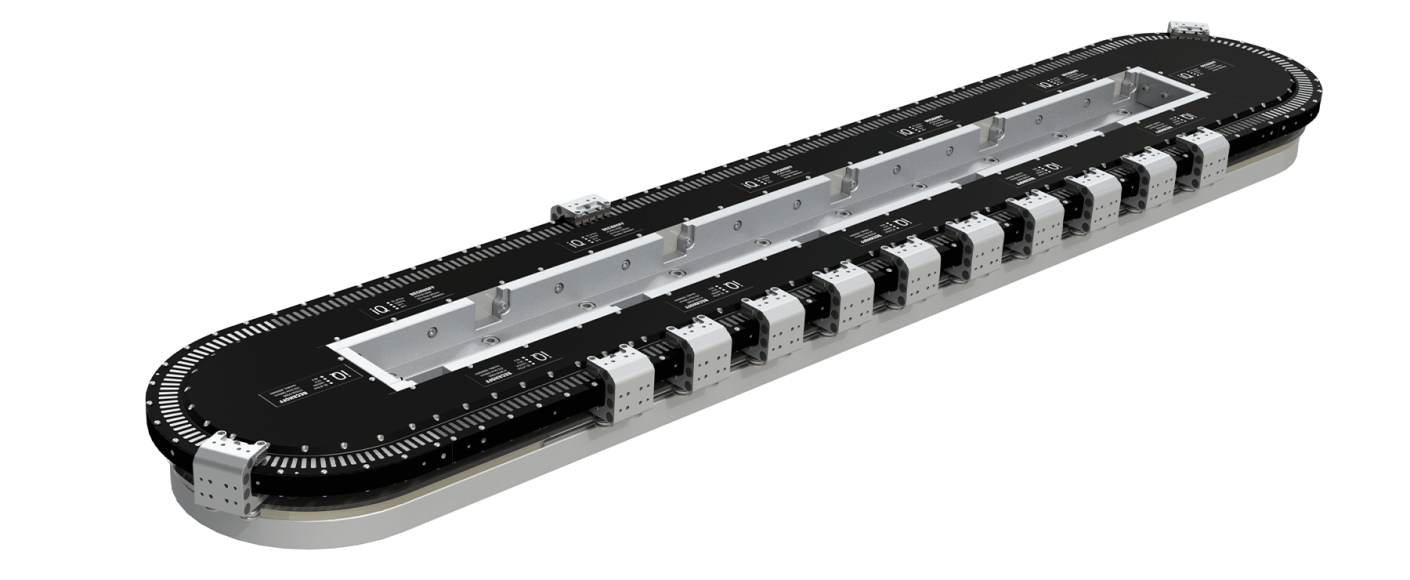

Light and fast – GFX Agile bearings are smaller with a lower mass than standard GFX bearings, which allows the movers to accelerate and decelerate to and from top speeds quicker.

Higher throughput – The transit time is therefore significantly less, allowing more parts per minute.

Lightweight applications – GFX Agile is perfect for lightweight applications, with little or no process loading, such as the packaging or filling of small confectionary or pharmaceutical products.

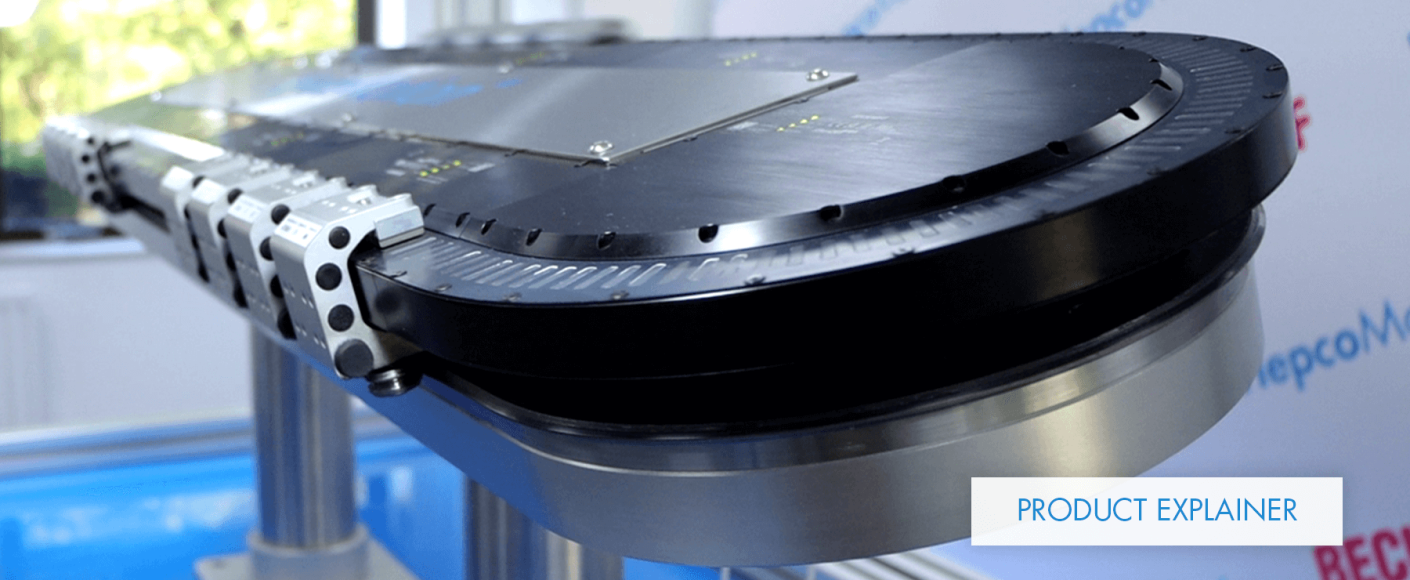

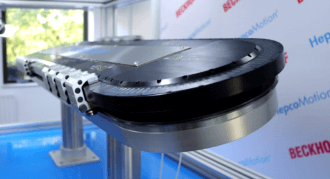

HepcoMotion and Beckhoff – HepcoMotion works in partnership with Beckhoff to create the GFX system, a high-end track system that provides the support and rigidity required for precise XTS applications.

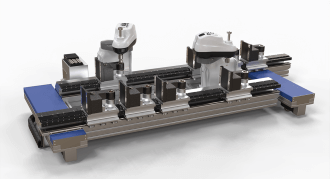

Flexible – The Beckhoff XTS Transport System uses linear motor technology to independently drive movers around a track. This allows work processes of different duration to be combined, on the fly product changes, and the addition or removal of workstations as needed.

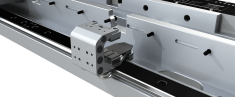

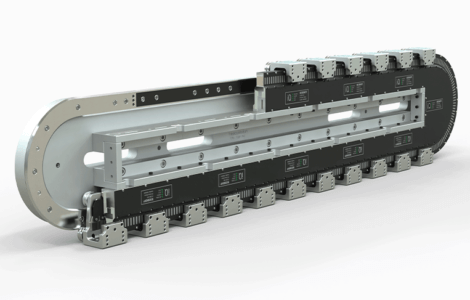

Precise and reliable – GFX provides the transport path and mechanically guides the movers along the motor modules at the defined speed, with great precision, ensuring accurate alignment and resistance to deflection.

Long system life – GFX is designed to accommodate complex, high-speed motion profiles requiring extended duty cycles.

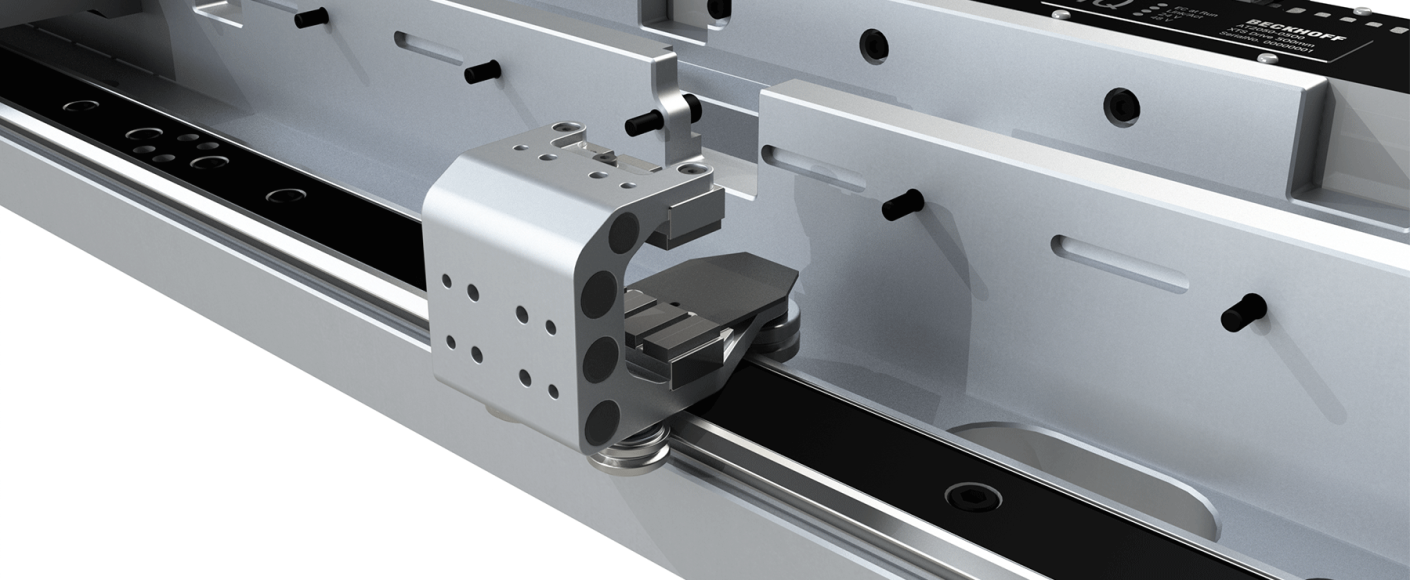

Low maintenance – Thanks to HepcoMotion’s V guide technology, the system requires very little maintenance to achieve consistently high performance.

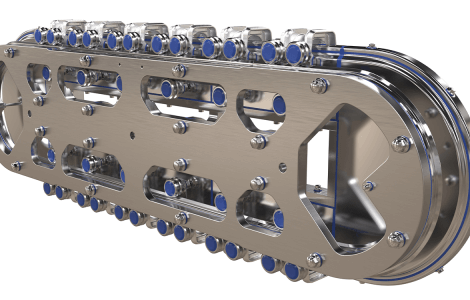

- GFX can be supplied fully assembled, with Beckhoff motor modules, mover magnets and mover encoder flags, partially assembled, or as a kit of components

- Agile uses standard GFX track and baseplate components

- The motor mounting bracket is more compact to allow for the much smaller bearing offset of the mover body

- Simplified lubrication system enables use in high duty cycle production environments, food compatible lubricants can be used

- The system offers a superior positional accuracy of +/- 0.05mm even at high speed

- The number and spacing of the movers is flexible

- To maximise system life, GFX includes integrated bleed lubrication

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form