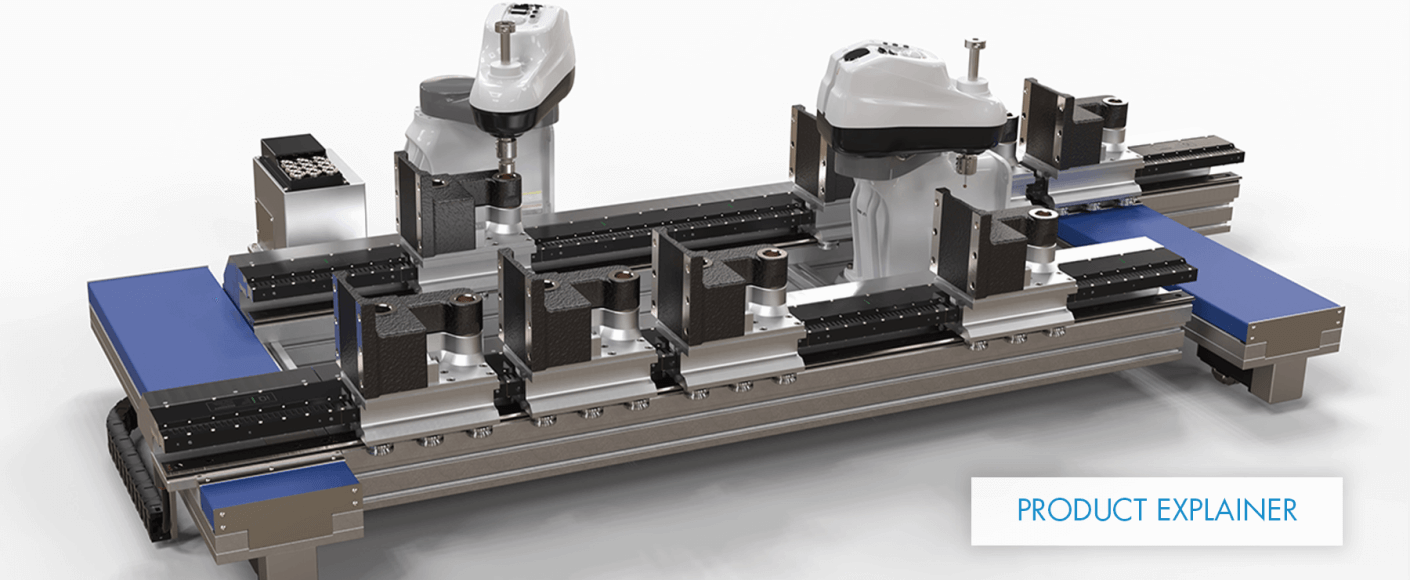

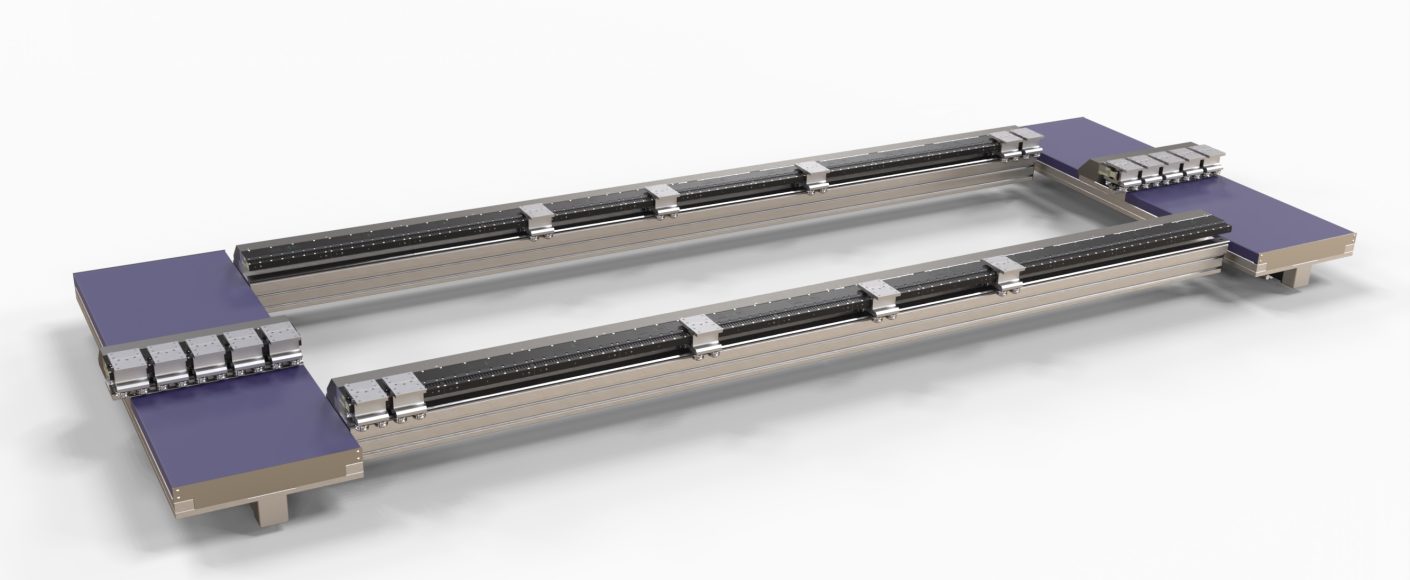

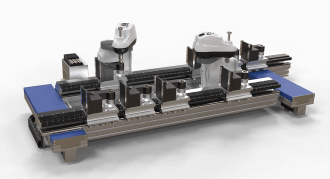

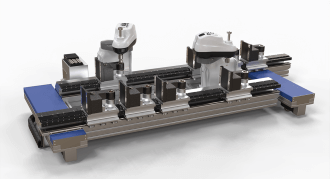

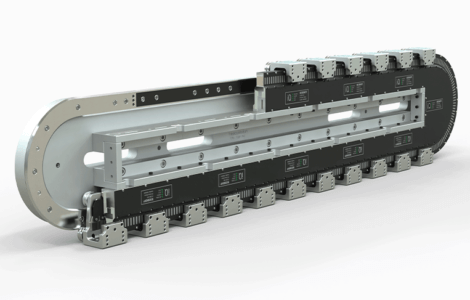

Featuring the inherent flexibility and precision of GFX/XTS technology, GFX-r provides movement in rectangular paths catering for higher payloads and increased in-process stresses.

Increased payload – Based on the existing GFX, the curved segments have been removed, enabling wider bearing spacing for transporting increased payloads of up to 100kg. XTS 7 & 10 pole magnet arrays provide the enhanced drive capacity.

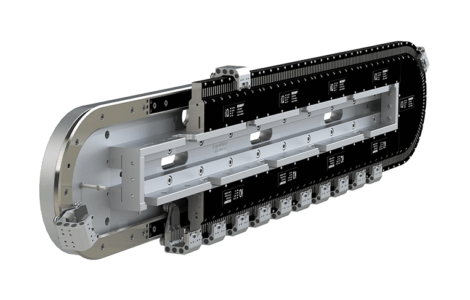

Integration of expertise – GFX-r integrates Beckhoff and Hepco’s expertise, featuring larger movers and collaborative Transport Modules to complete the rectangular path, transitioning the movers between tracks whilst retaining positional accuracy.

Demanding applications – GFX-r excels in handling substantial moment loads and heightened in-process stresses, making it an ideal choice for machine cells incorporating robots, power tools, and sensors, as well as automated assembly and inspection systems.

Movement in rectangular paths – Not only does a rectangular path facilitate a higher payload, it also makes GFX-r ideally suited to applications requiring a constant product orientation.

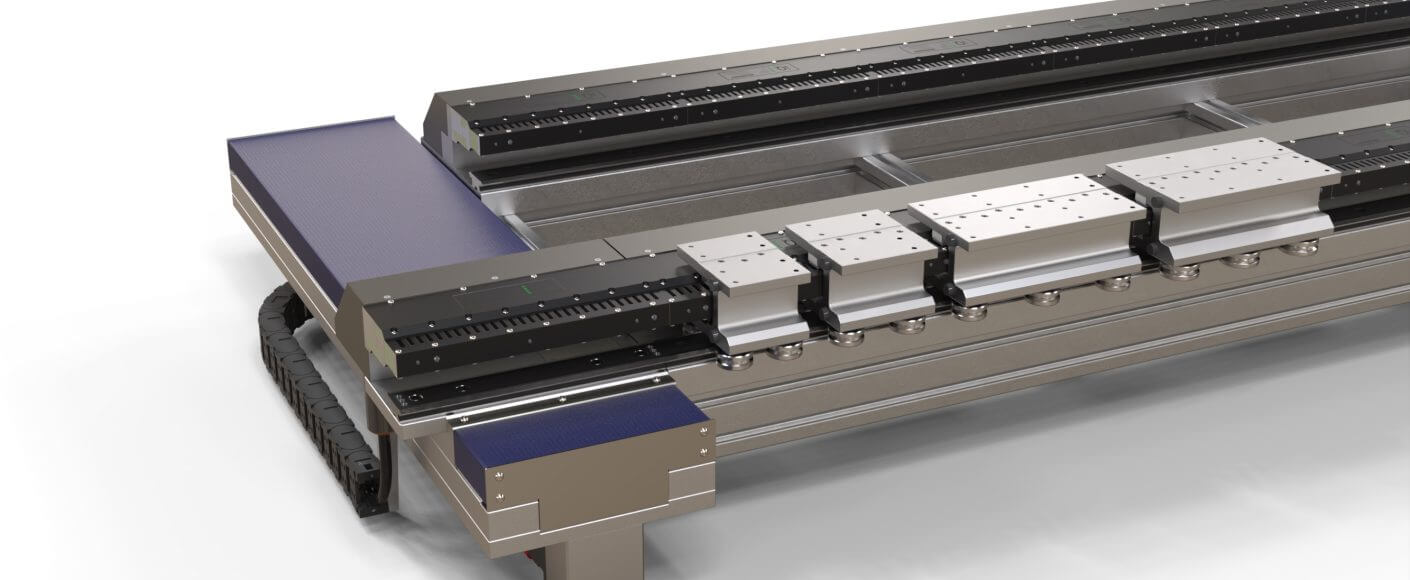

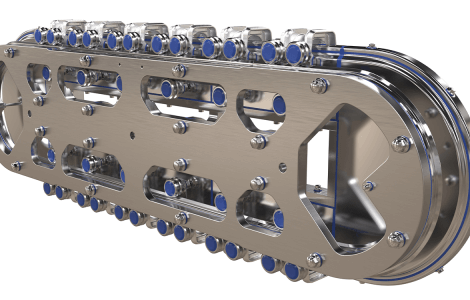

HepcoMotion and Beckhoff – For the last ten years, Hepco and Beckhoff have collaborated on the GFX system, a high-end track system that provides the support and rigidity required for precise XTS applications.

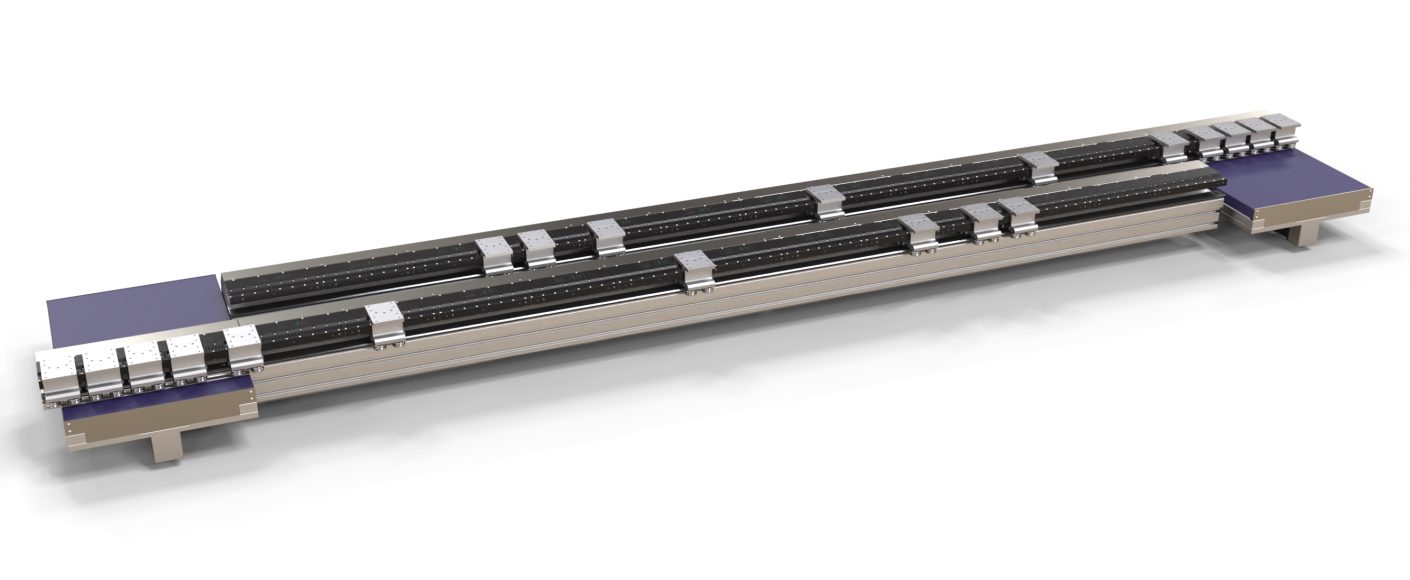

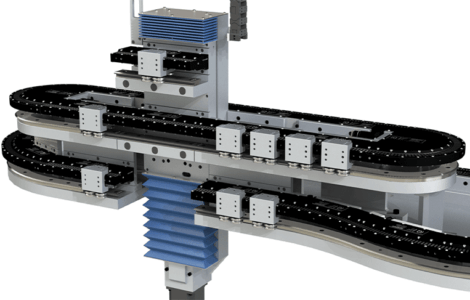

Flexible – Beckhoff’s XTS Transport System uses linear motor technology to independently drive movers around a track, allowing work processes of different duration to be combined, on the fly product changes, and the addition or removal of workstations as needed.

Precise and reliable – GFX serves as the transport path, mechanically guiding the movers along the motor modules at defined speed, with great precision, ensuring accurate alignment and resistance to deflection.

Low maintenance – Thanks to HepcoMotion’s V guide technology, the system requires very little maintenance to achieve consistently high performance.

- GFX can be supplied fully assembled, with Beckhoff motor modules, mover magnets and mover encoder flags, partially assembled, or as a kit of components

- Simplified lubrication system enables use in high duty cycle production environments, food compatible lubricants can be used

- The system offers a superior positional accuracy of +/- 0.02mm even at high speed

- The number and spacing of the movers is flexible

- To maximise system life, GFX includes integrated bleed lubrication

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form