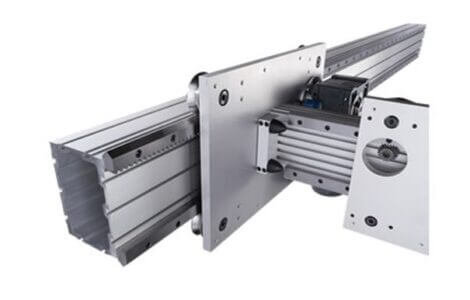

Hepco's Maximum Heavy Duty (MHD) 7th Axis track system combines linear and curved motion, expanding the range of movement for 7th axis robots, enabling more versatile and dynamic motion.

Curved 7th axis robot transfer – This unique development enables 7th axis robot transfer systems to travel around curved and straight sections of track, providing opportunities for automation that were not previously possible.

Freely configurable layout – By combining curved and straight segments, almost unlimited 2D-shaped track layouts can be created to meet the exact requirements of the application.

Design flexibility – Oval, rectangular, circular, ‘J’, ‘U’ and ‘S’ shapes are available as standard. Closed and open circuits can be specified.

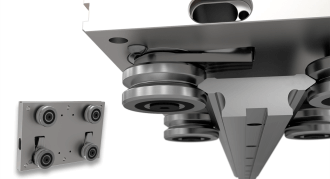

Tracks of varying radii – The unique bogie mechanism means a single carriage can travel around curves of different radii and varying directions on the same track system.

Caters for high moment load – The large carriage size offers stability, high moment load capacity and can withstand the forces generated by E-stop conditions.

Durable – High capacity twin taper roller bearings provide accurate, durable and low-friction movement. The bearings are sealed for life, making them tolerant of debris.

Low maintenance – Lubricators in the bearing blocks apply a coating of oil to each bearing to maximise life.

Drive flange & geared motor – The integrated drive flange assembly allows for mounting a geared motor to drive the carriage, whilst leaving a large platform for the fitting of robotics or other equipment.

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form