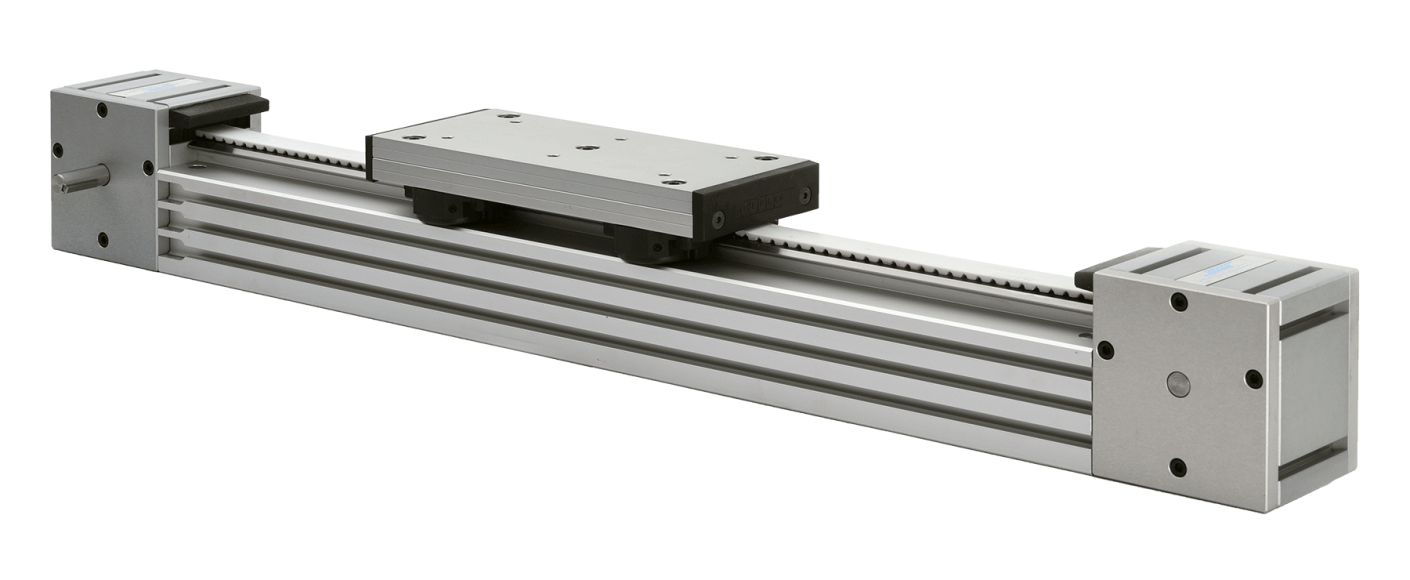

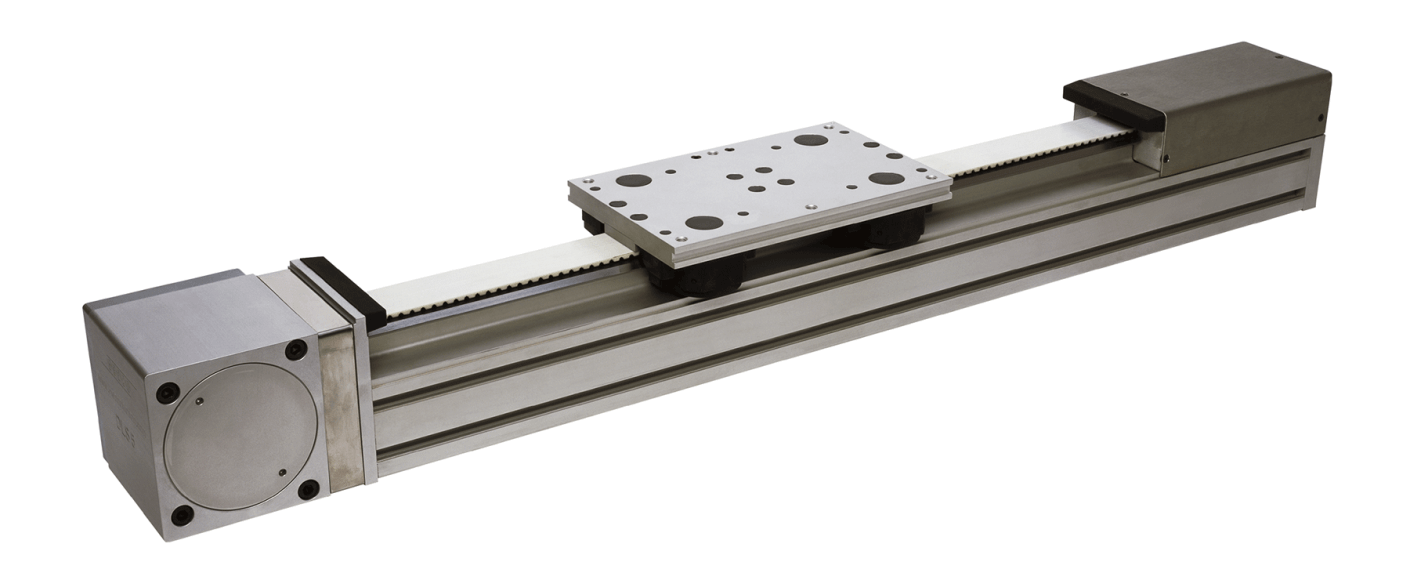

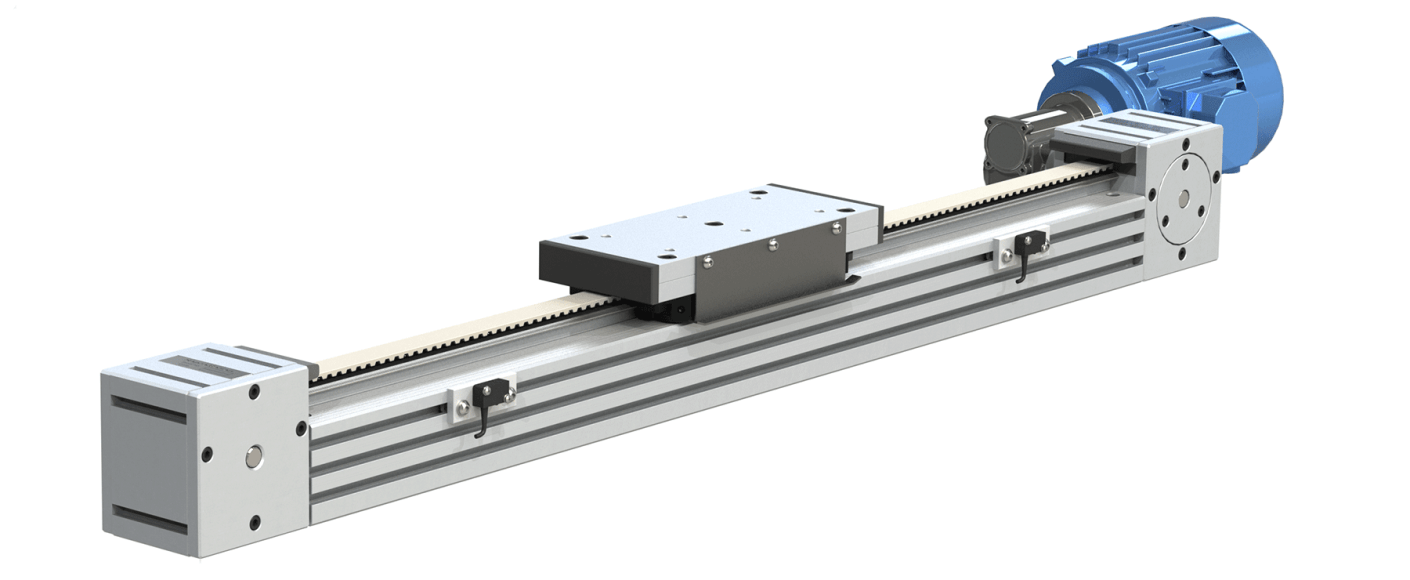

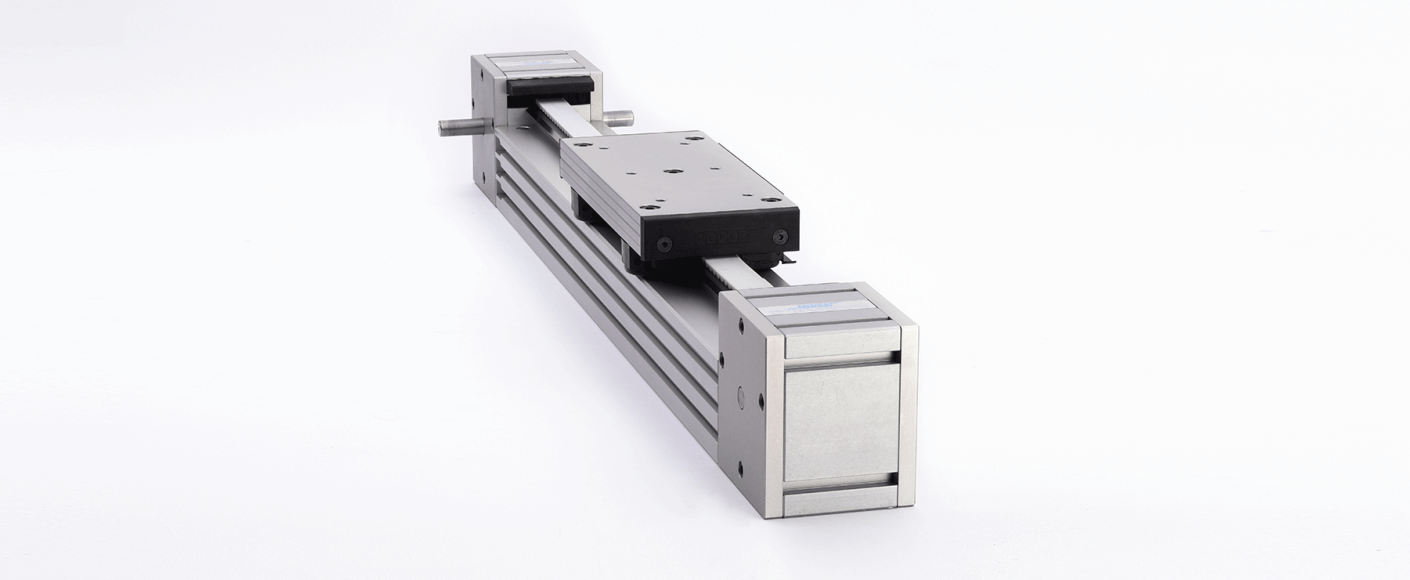

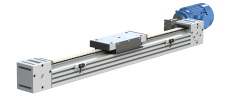

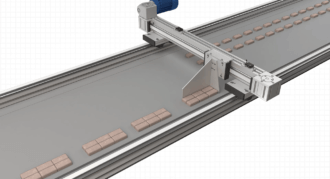

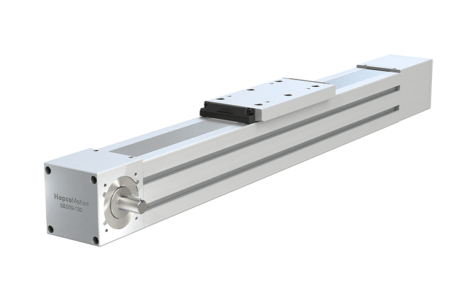

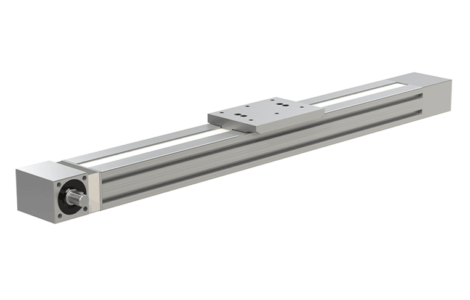

A complete linear drive solution, providing accurate precision and a modular design, HepcoMotion’s DLS Belt Driven Linear Actuator is ideally suited to many positioning applications.

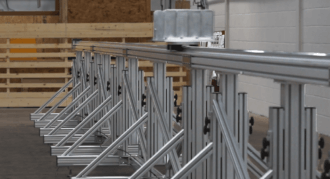

Saves time and money – A fully assembled driven unit, DLS will save hours in design and assembly time.

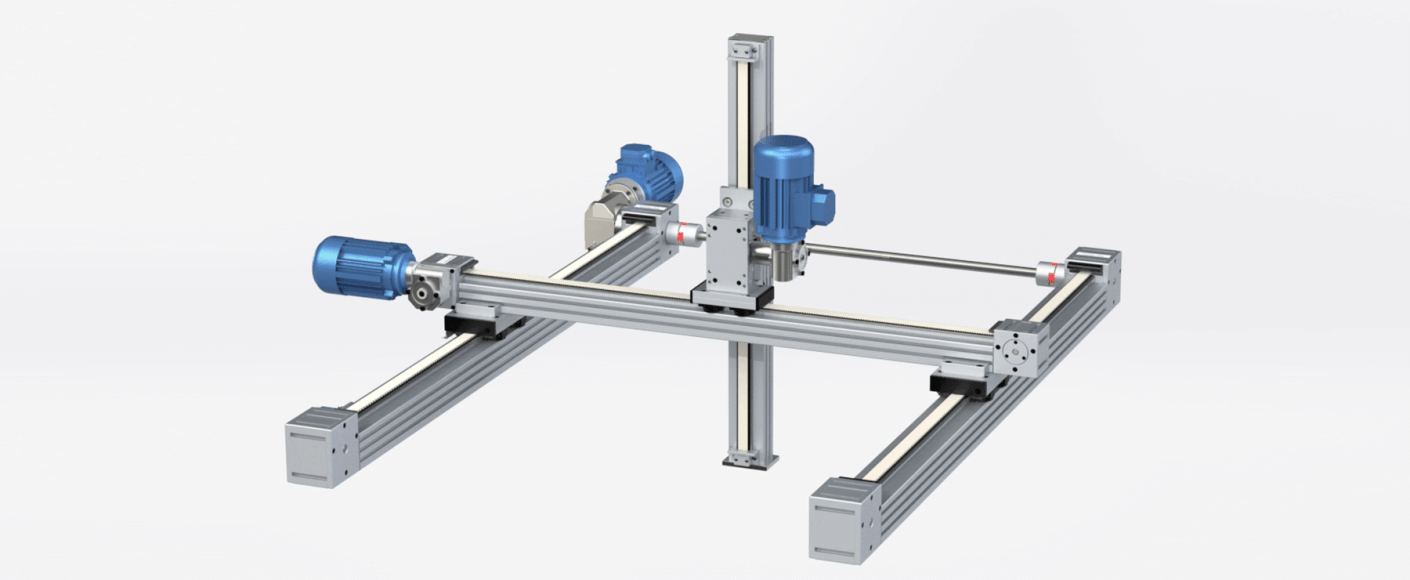

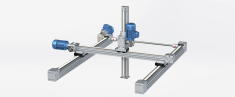

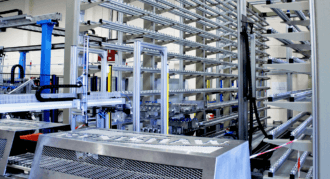

Modular system with bespoke options – Multiple sizes and configurations are available for ultimate convenience and flexibility. Bespoke lengths up to 8m as standard, with longer lengths available with joined beams.

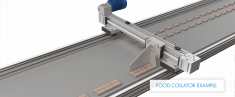

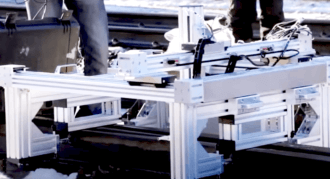

Suitable for washdown and clean room environments – Corrosive resistant options are available.

Reliable and low maintenance – Thanks to V guide technology costly unplanned downtime is minimised, allowing production lines to continue un-interrupted.

A zero backlash system – DLS ensures excellent positional accuracy and repeatability; fundamental requirements for many applications.

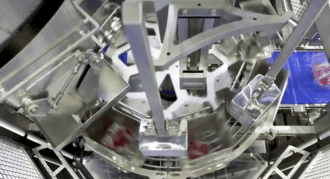

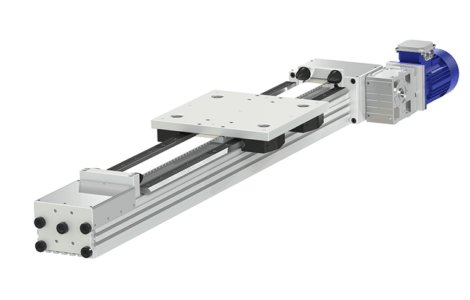

Multiple drive choices – Keyed input shaft, custom motor connection kits, planetary gearboxes and a standard range of AC geared motors provide a drive solution for most needs.

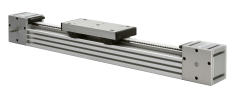

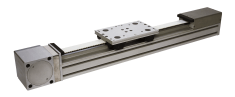

- Hardened and precision ground linear slide

- Double row cap sealed bearings for long system life and low maintenance

- Polyurethane steel-reinforced belt for minimum stretch and high speed capability

- T-nut slots on beam and end boxes allow simple attachment of clamps and switches

- Removable carriage top plate for secondary machining (on DLS3 and DLS4)

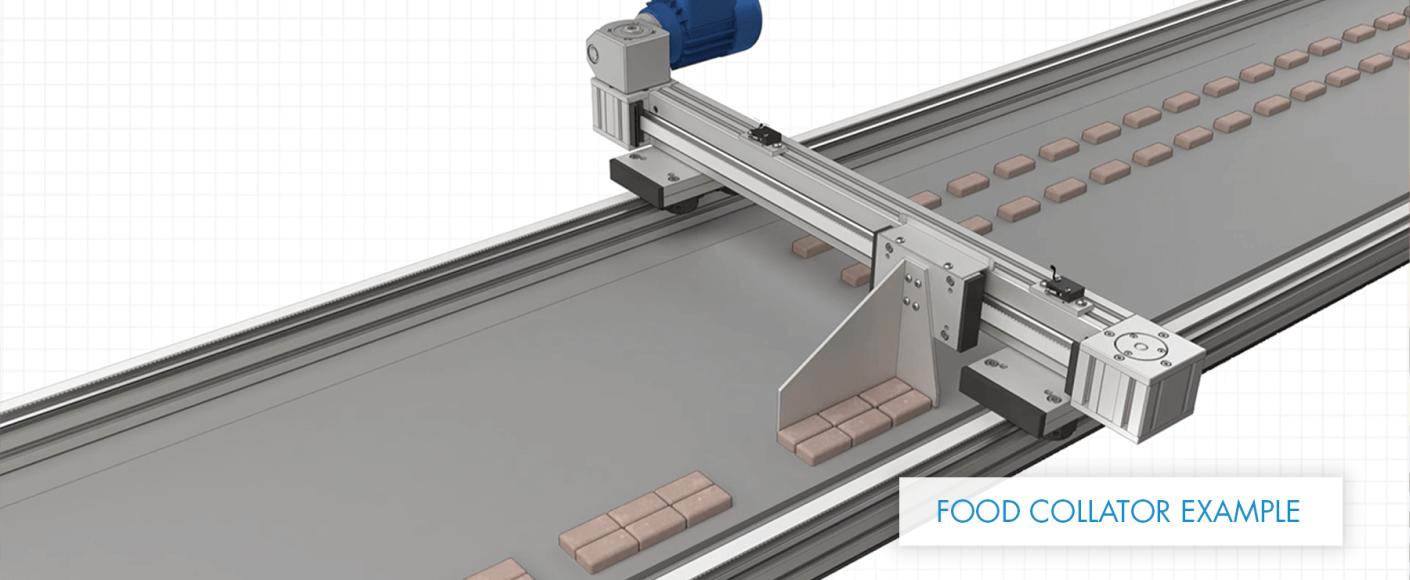

- Also available for Z axis, and horizontal pick and place

DLS Quick Selector

This diagram provides an overview of the bearing sizes available and their load capacity depending on the application type.

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form