Manual assembly processes can often involve supplying operators with fixtures holding sub assemblies that need components to be mounted.

In this application an automotive component supplier needed to locate plastic components from a number of bins located around the assembly area. The fixtures would then need to be moved to the next operator for an additional assembly process to take place. Motion needed to be low friction and smooth in order to prevent repetitive strain injuries.

Solution

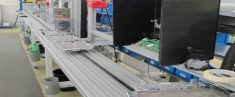

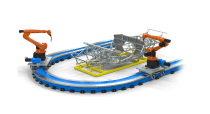

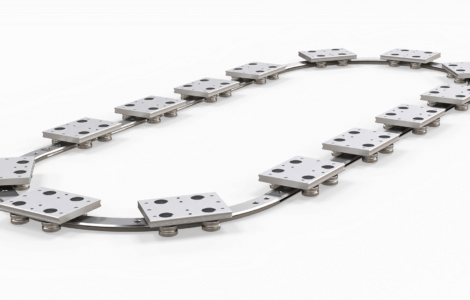

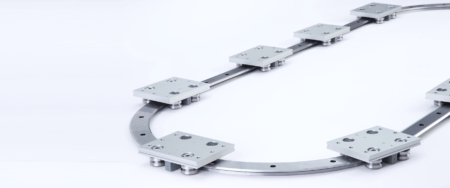

An oval shaped PRT2 system size 25, 3m long x 1.5 m wide located around the component bins with 6 carriages placed around the circumference of the track. The track was fitted to aluminium profiles using the tee slots to locate the track slides and segments. The carriage plates were fitted with simple detachable fixtures depending on the component and assembly operation.

Scope of supply

TNS25 track slides 3000mm x 2 plus 1500mm x 2 with 4 segments TR25-351. 6 x Special carriages plates based around the standard FCC25-351 to suit the necessary fixtures.

Result

A simple easy solution demonstrating how PRT2 can be used even in a manual application with great effect. The use of ring and tracks in this application provided the operators with an easy to move carriage with low friction characteristics without fear of repetitive strain injuries.

Recommended for you

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form