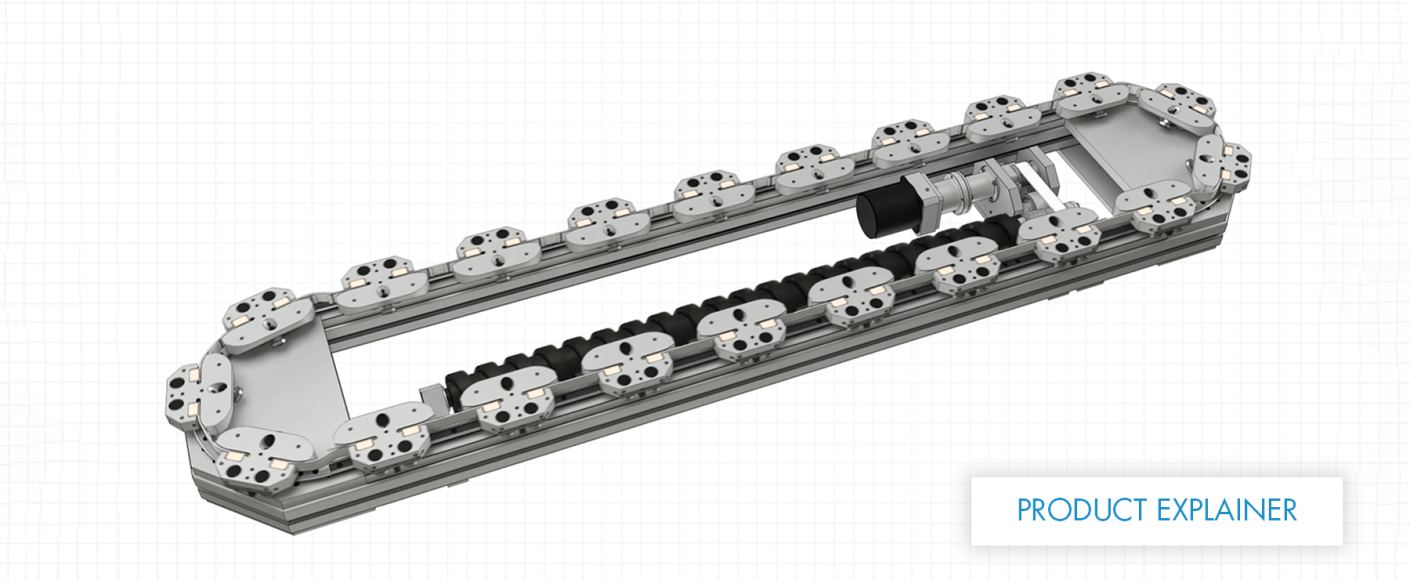

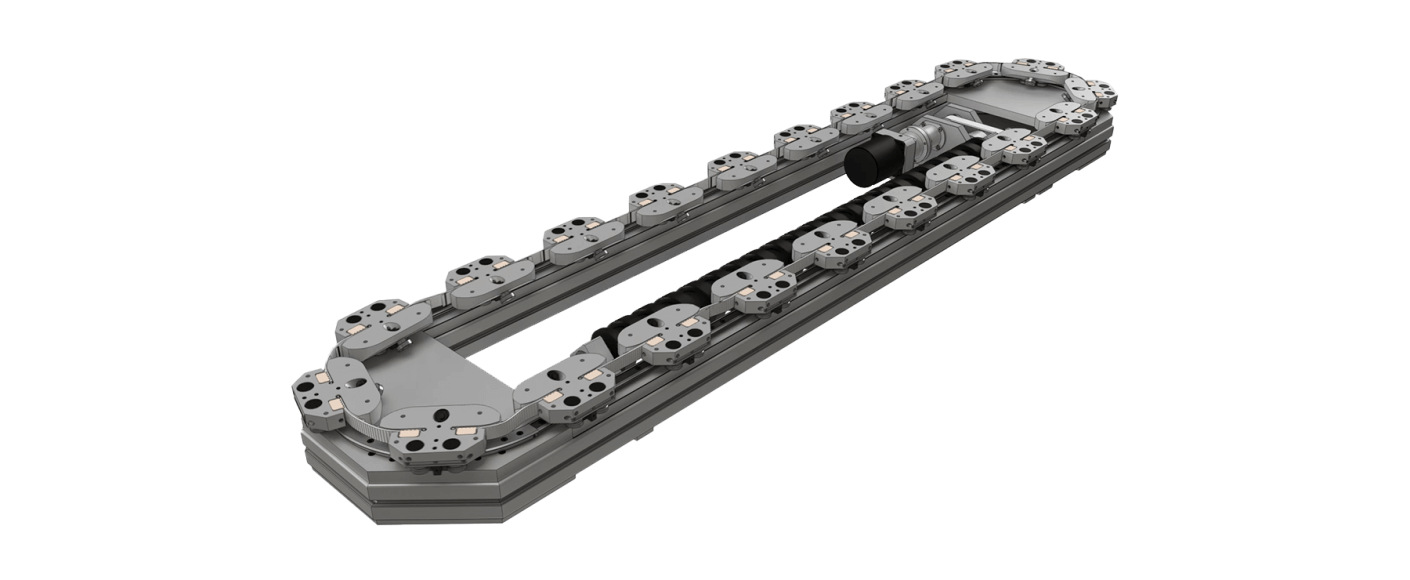

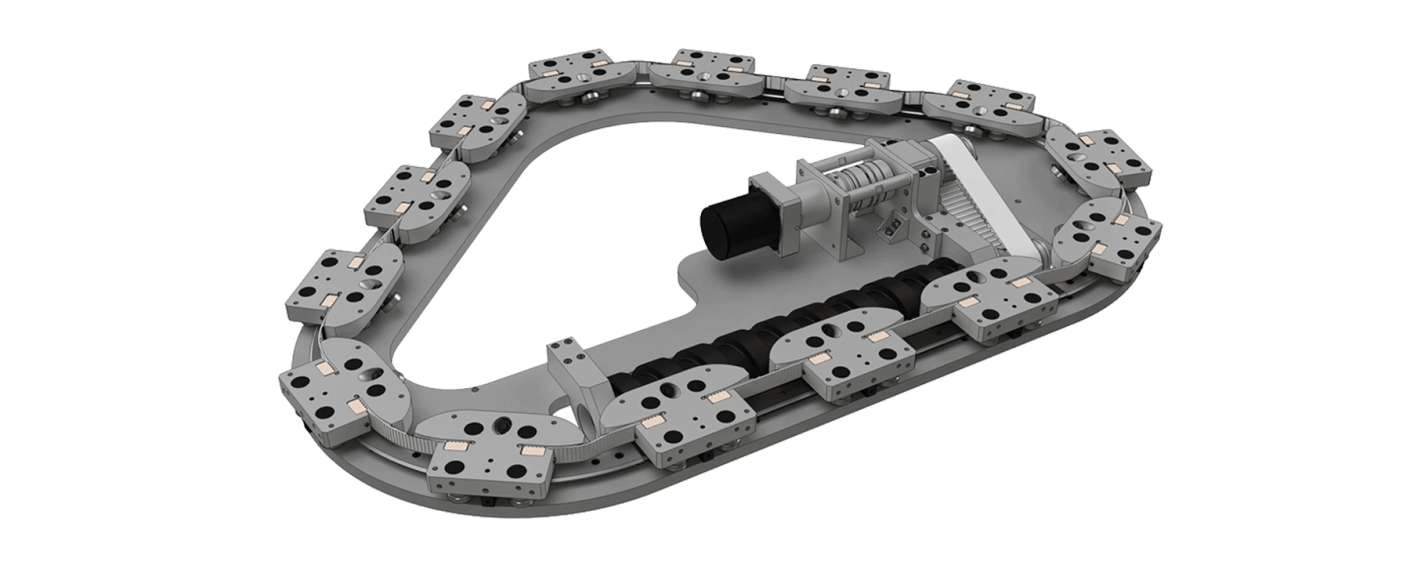

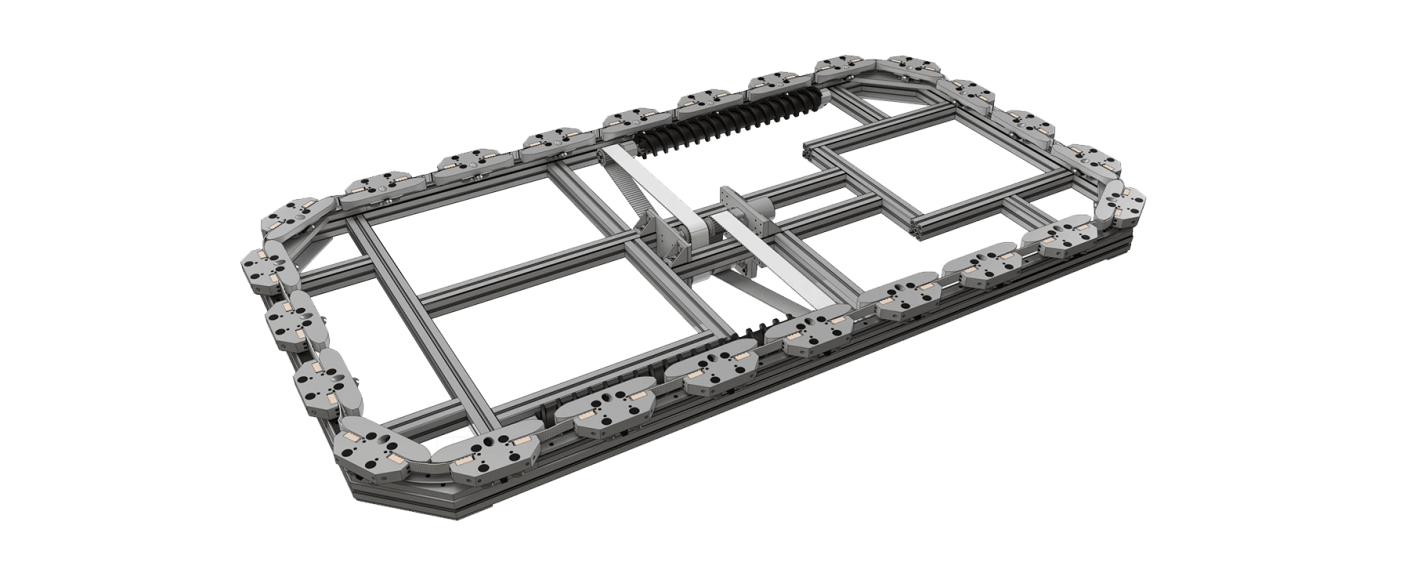

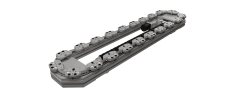

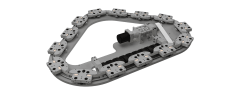

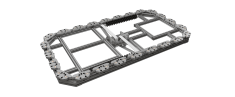

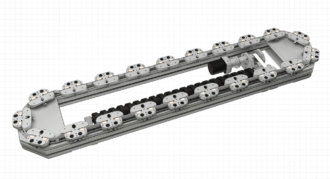

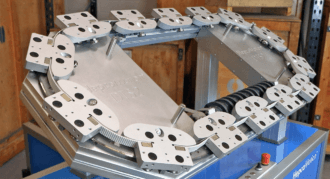

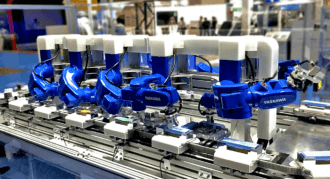

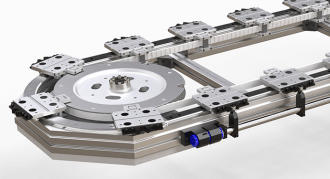

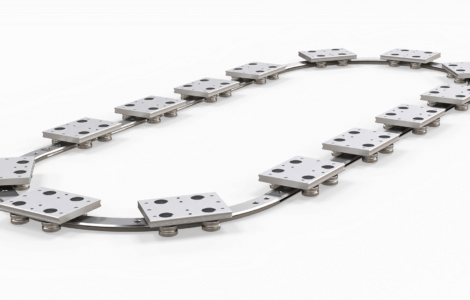

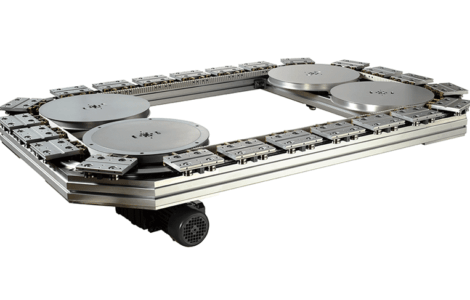

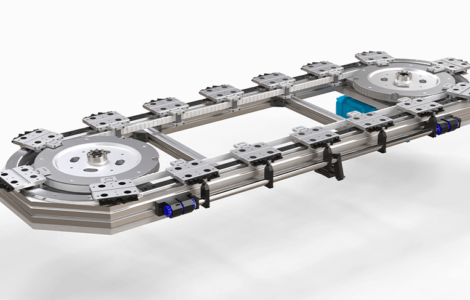

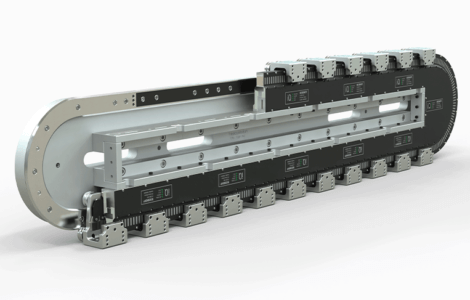

DTS2 is a ready to fit scroll driven track system for high speed and rapid indexing applications requiring smooth movement.

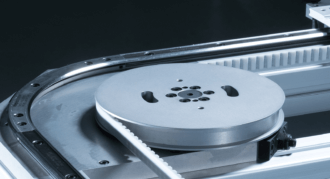

Strong drive for quick and accurate indexing – The scroll drive enables DTS2 carriages to accept high driving forces, allowing rapid indexing with high accelerations, and superior positional accuracy of +/-0.2mm, without the risk of carriage disengagement.

Smooth and quick motion – The speed of the carriages is the same on the curved segments as it is on the straights, resulting in a consistent, smooth motion of up to 3m/s.

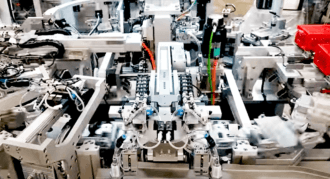

Reduced process cost – Enables complex production routing and disconnected processes to be contained within one single continuous loop.

Reduced design and installation time – As a ready to fit system, DTS2 minimises design time and cost and is simple to install and operate.

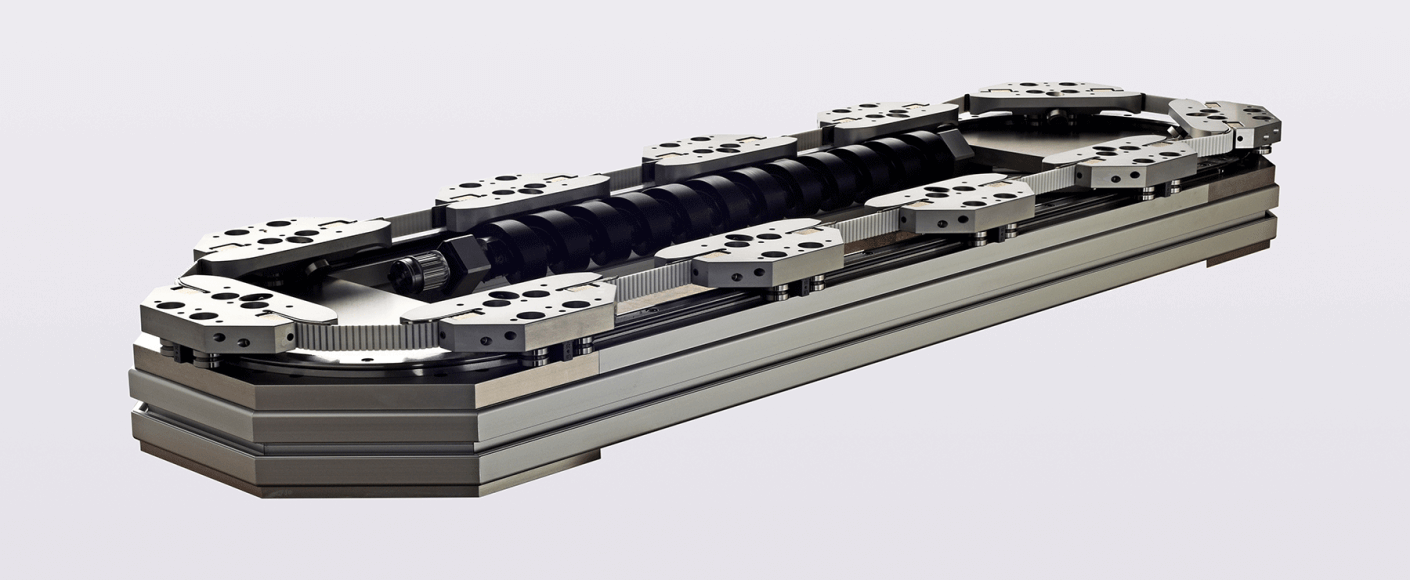

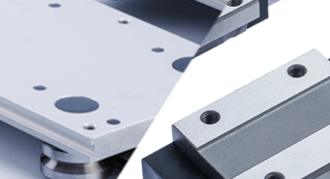

Precise and repeatable – A carriage locking option aligns specific carriages to a repeatable position anywhere along any straight section of the circuit to +/-0.05 mm.

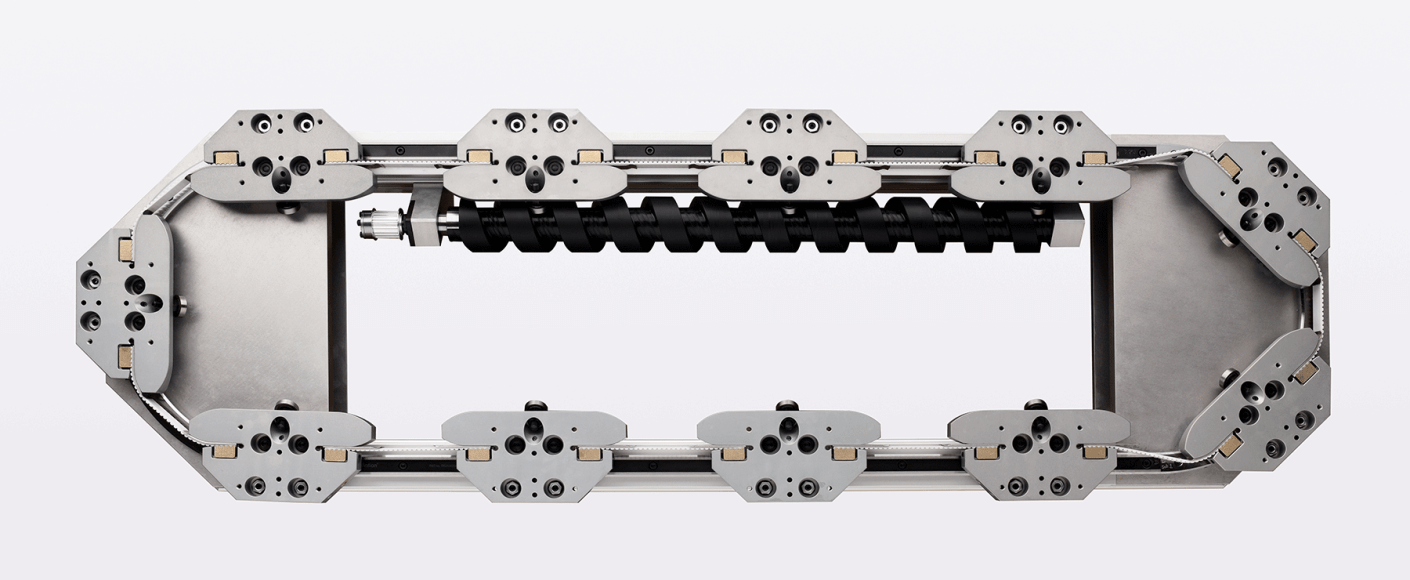

Versatile – DTS2 can be installed horizontally or vertically and features an extremely small profile. Thanks to its design, equipment can be located inside or outside of the track shape, saving valuable production space.

Carriages will not disengage – The superior drive strength of the DTS2 will not disengage the carriage from the drive in the event of an overload.

Reduced downtime – Hepco’s bleed lubrication system provides constant lubrication to the contact surface between the track and V bearings, eliminating the need to stop production lines regularly for re-lubrication.

Suitable for hostile environments – Thanks to HepcoMotion’s V guide technology, the system works well in environments that produce dust or dirt particles.

Perfect for any component assembly line in all industries requiring a higher speed than the standard DTS system.

- Available in 2 rail sizes (25 and 44mm)

- Flexibility with carriage length, number and positioning of carriages, subject to minimum technical requirements

- Available in stainless steel, with all track, bearing, springs and fasteners in stainless steel

- Flexible drive positioning

- Drive screws are manufactured from high quality bearing grade polymer, designed specifically to match the requirements of the application

- Carriages will normally be made in aluminium alloy with a food compatible corrosion resistant coating

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form