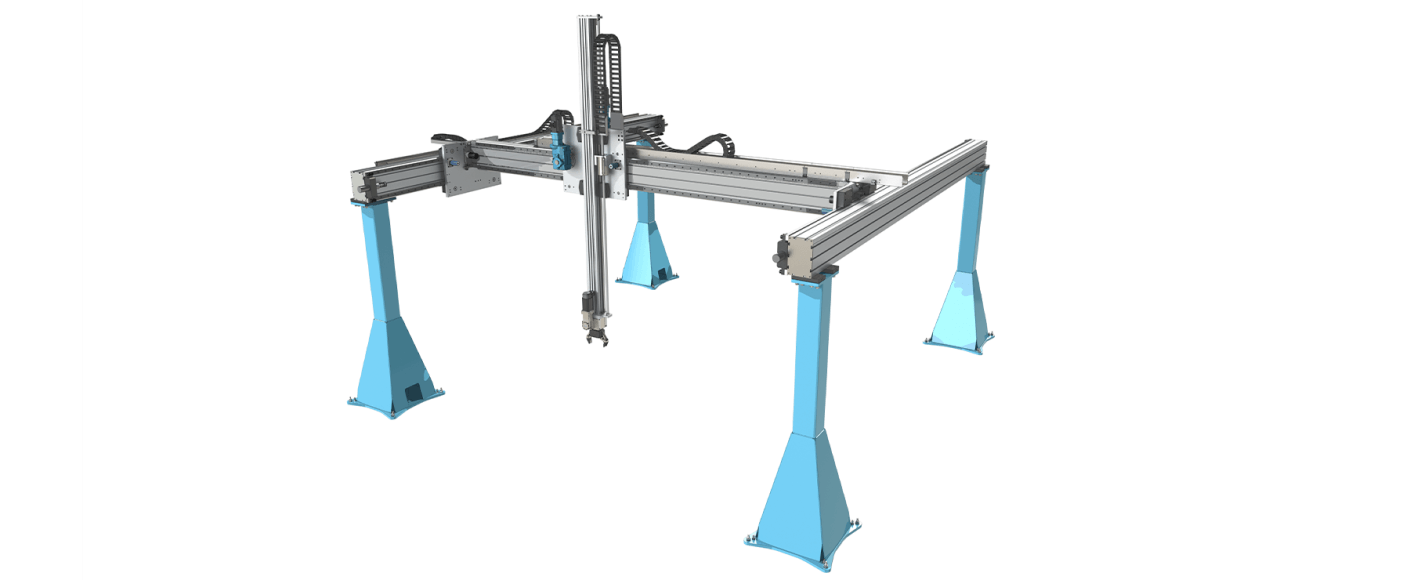

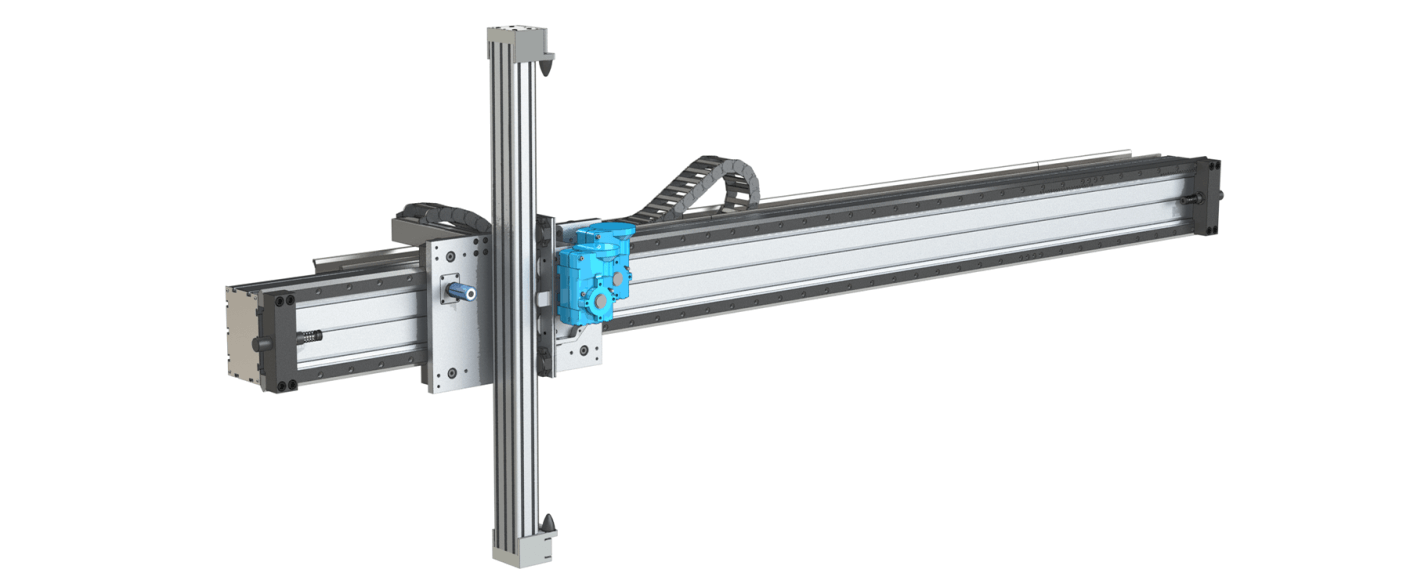

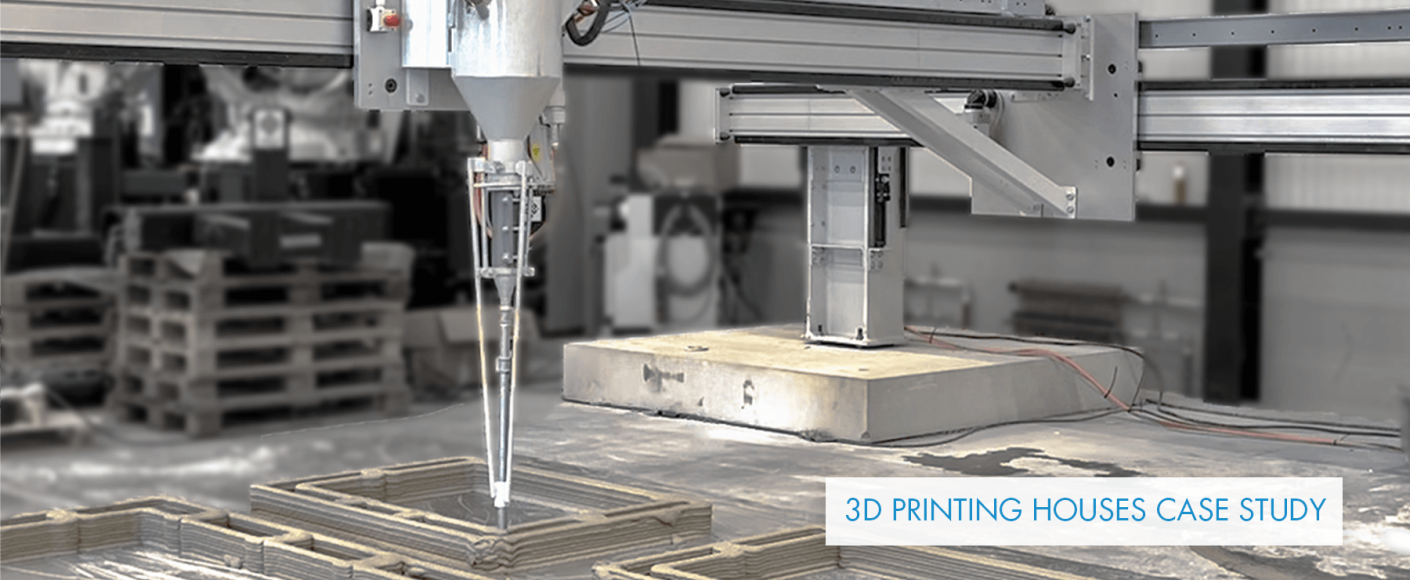

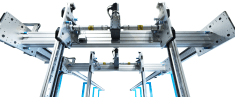

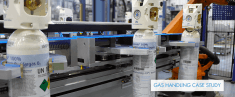

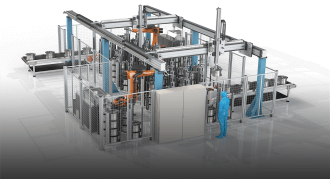

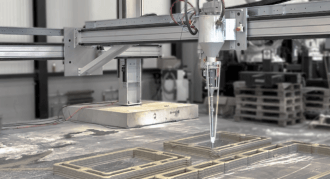

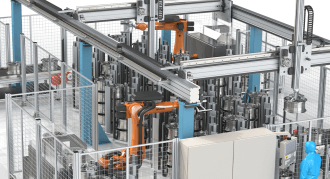

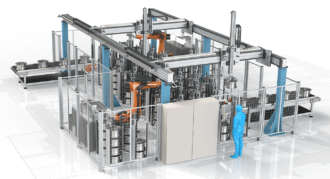

HepcoMotion’s heavy duty V guide system can be configured into multi-axis gantry systems to achieve automation for applications such as palletizing, sorting, and pick & place.

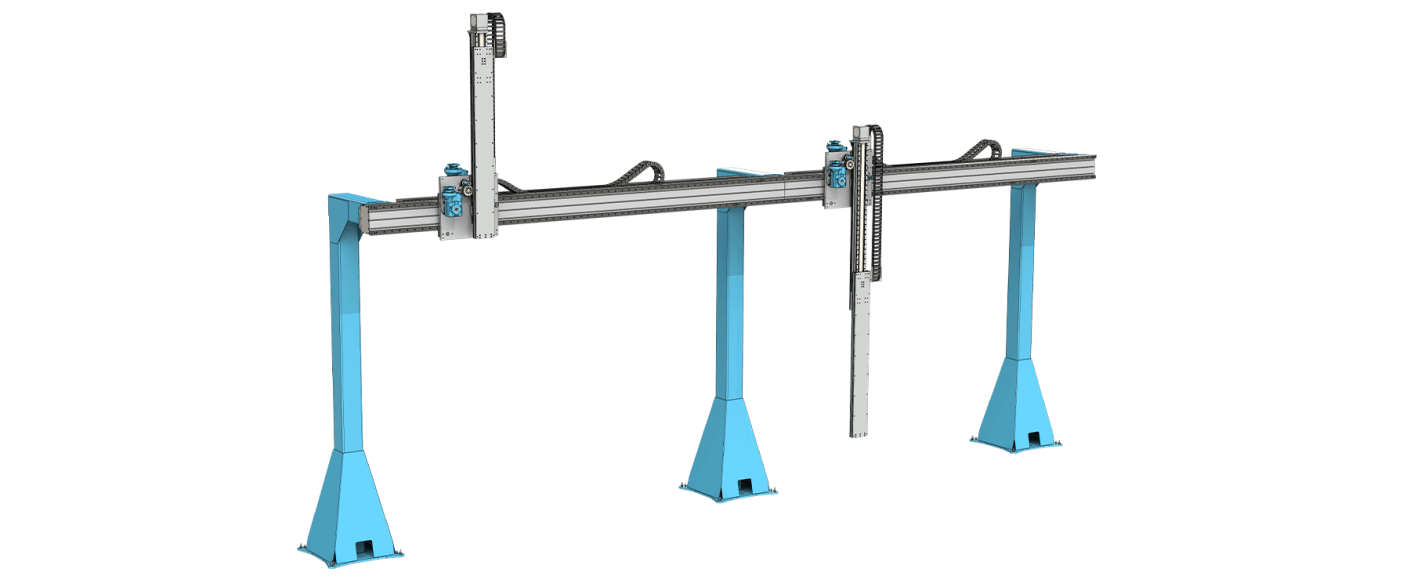

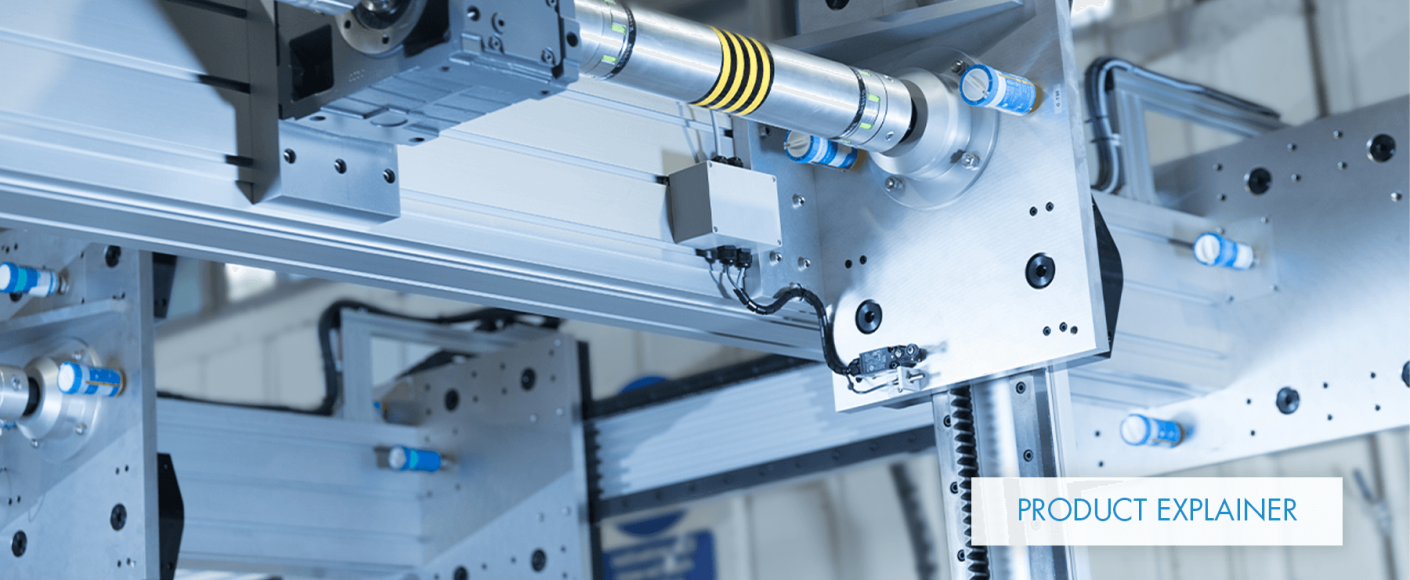

Heavy loads and large work areas – Based on the HDS2 heavy duty range, Hepco’s gantry systems are ideally suited for precisely moving heavy payloads in large work areas.

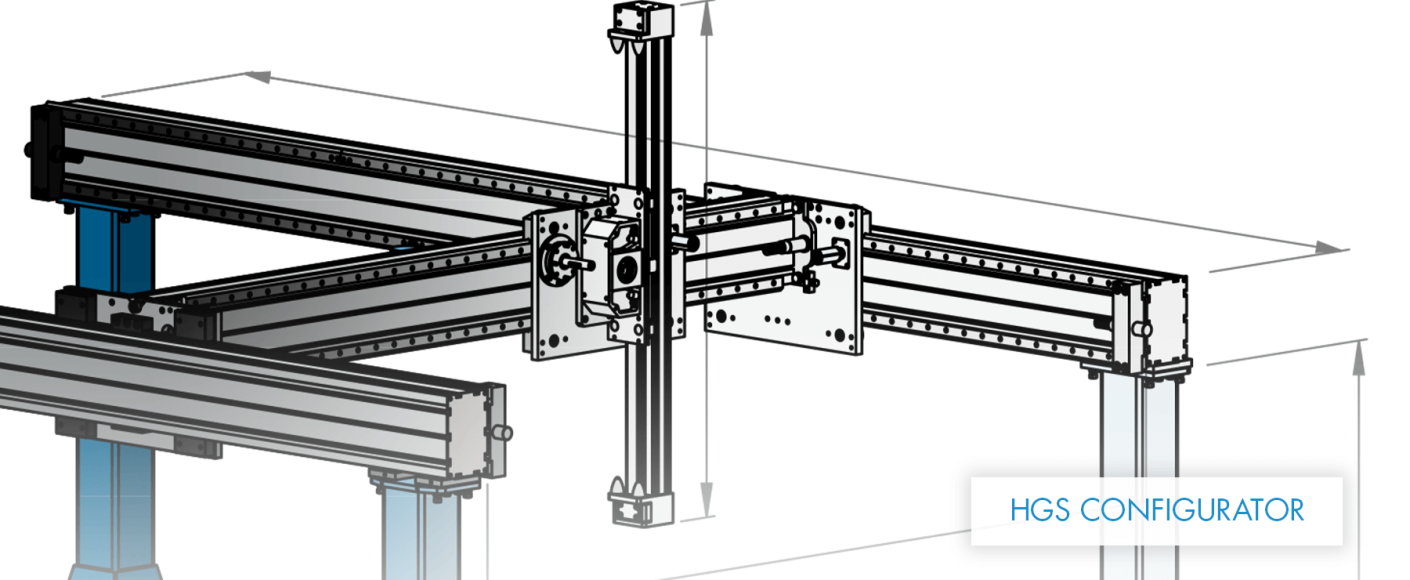

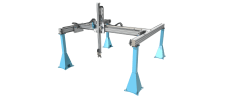

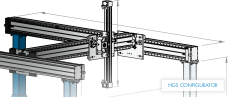

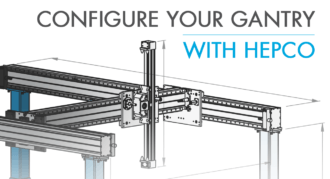

The core of many automated applications – Standard gantry configurations include XZ, XYZ and X. Bespoke designs are also available, saving considerable design time.

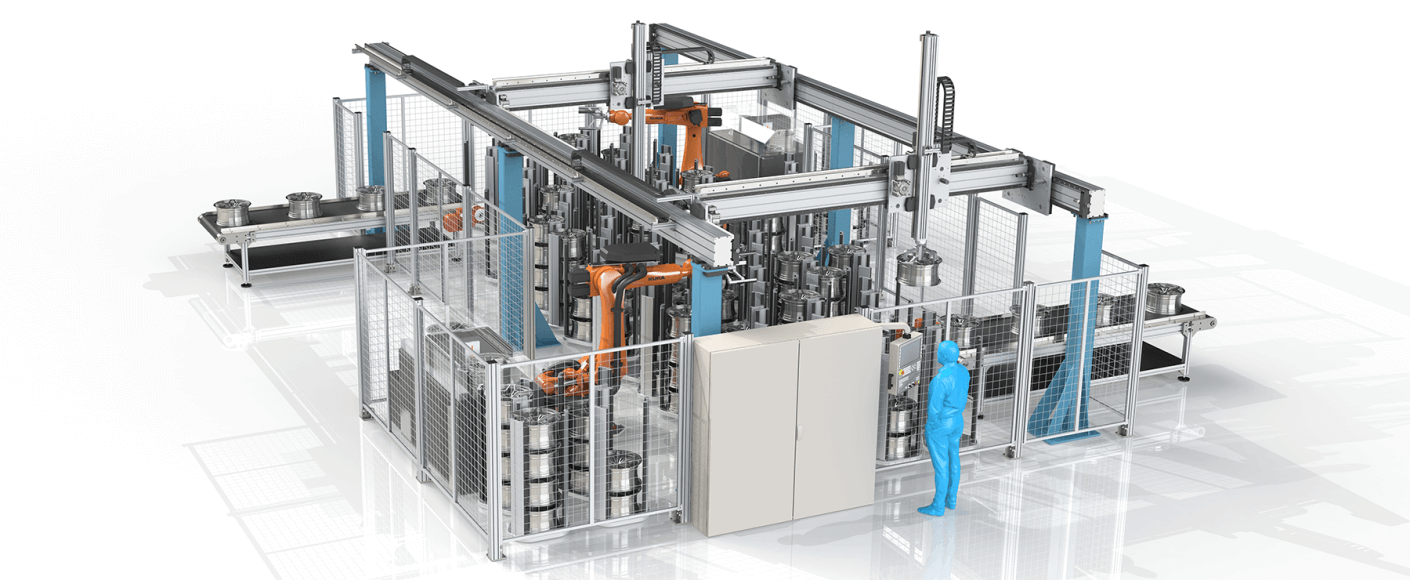

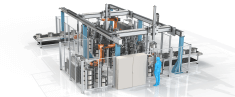

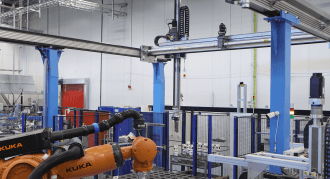

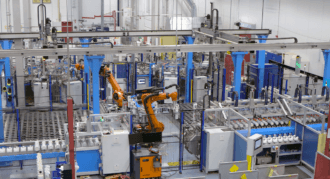

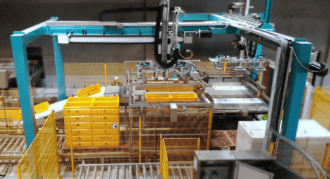

System integration – HepcoMotion gantries can be integrated with existing processes and equipment. Robot integration can greatly increase throughput and reduce manual handling of products and material.

Turnkey gantry solutions – HepcoAutomation can provide standard drive and control systems for any gantry application, managing the project from concept to completion.

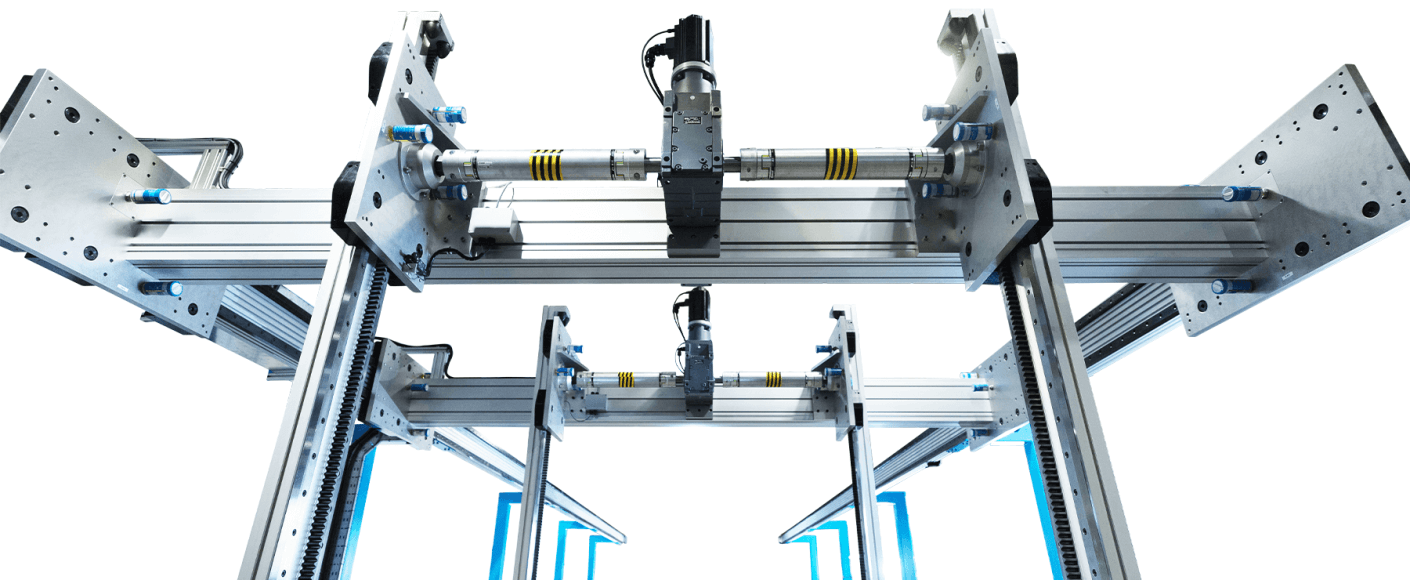

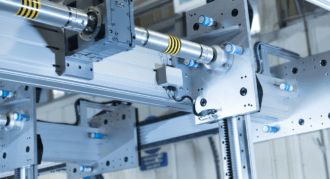

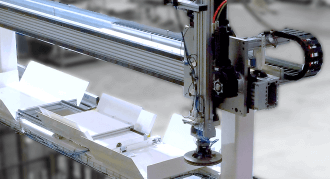

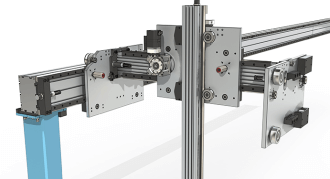

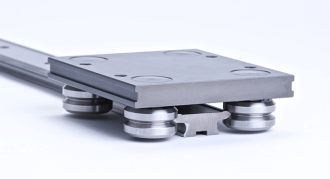

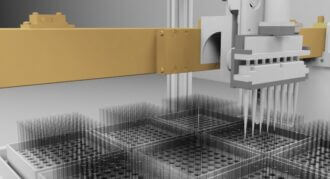

Low maintenance and long life – Hepco’s robust heavy duty V guide system is suitable for the harshest environments, and requires little maintenance, making V guide systems perfect for enclosed systems.

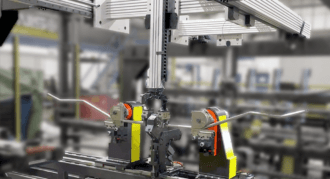

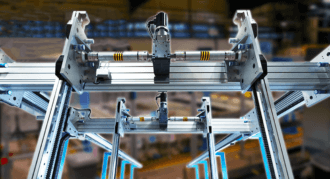

No need for absolute parallelism – The combination of V guide bearings, and roller bearings and flat tracks on a single axis allows for slight discrepancies in the parallelism, reducing setup times.

Modular system – Components can be easily combined as and when required, and systems can be extended, increasing flexibility and future-proofing installations.

Extensive application support – Alongside a dedicated team of sales & technical design engineers, Hepco’s Gantry System configuration tool will automatically specify an application and generate CAD models as required.

- Wide range of driven gantry systems including belt, ball screw, rack and pinion

- Extensive application support provided, including specification calculator to determine base requirements and performance optimisation

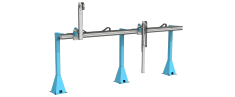

- A range of standard support legs are available to suit the application and space requirements

- Compatible with Hepco’s MCS aluminium profile range

Contact us

Tel Sales Enquiries +91 95151 31370 General Enquiries +91 94208 61817

Email [email protected]

Address

V Edge Slide Systems India Private Limited

Office A-5, Mahesh Galaxy

Vadgaon Budruk,

Pune, Maharashtra 411041

India

Contact Form